What is the general tolerance for ceramic dowel pin holes?

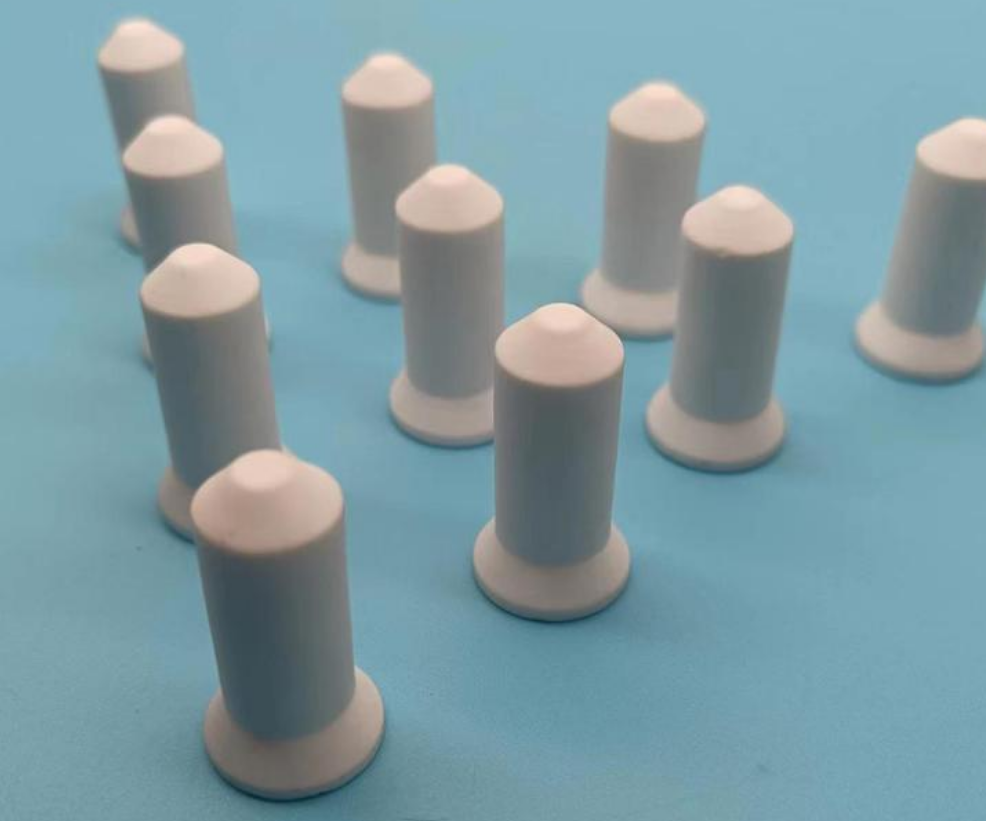

In mechanical manufacturing and assembly, the tolerance of the ceramic locating pin hole is a key parameter, which directly affects the stability and assembly accuracy of the ceramic locating pin.

Tolerance refers to the allowable deviation range between the actual size of a part and its designed size. For the ceramic dowel pin holes, the tolerance range must be precisely controlled to ensure that the ceramic dowel pins can be stably inserted and fixed into the two parts.

The tolerance of ceramic dowel pin holes generally depends on the following factors:

Manufacturing process

Different manufacturing processes (such as casting, forging, machining, etc.) have different effects on the size and shape of the hole. Some errors may occur during the manufacturing process, so the influence of the process on the tolerance needs to be considered.

Material properties

The thermal expansion coefficient, hardness and other properties of the material will affect the dimensional changes of the holes. In high or low temperature environments, materials may expand or contract, causing changes in the size of the holes.

Assembly requirements

Different assembly requirements have different requirements for the tolerance of holes. For example, for assemblies with high precision requirements, the tolerance range of holes may be smaller; For general assembly requirements, the tolerance range of the holes may be larger.

According to common manufacturing and assembly practices, the tolerance range of ceramic dowel pin holes is usually between ±0.05mm and ±0.1mm. This scope takes into account the actual situation of most manufacturing processes and assembly requirements. Of course, for some occasions with high precision requirements, the tolerance range of the hole may need to be smaller.

The size of the tolerance of ceramic dowel pin holes usually depends on the distance between the pin holes. If the distance between two cylindrical pin holes is 100mm or less, the positional tolerance of the pin holes is generally ±0.01mm. The distance is between 100mm and 200mm, with a tolerance of ±0.015mm. Between 200mm and 300mm, with a tolerance of ±0.02mm; When it exceeds 300mm, the tolerance is ±0.04mm. In simple terms, the longer the distance, the greater the allowable error will be.

It should be noted that the specific tolerance range should be determined based on the actual application conditions. During the design stage, factors such as manufacturing processes, material properties and assembly requirements should be fully considered to determine the appropriate hole tolerance range. Meanwhile, during the processing and inspection, effective quality control measures should be taken to ensure that the size and shape of the holes meet the design requirements.