Methods for the CNC machining process of thin wall ceramic parts

Here are some improvement methods for the CNC machining process of thin wall ceramic parts. Let's take a look

When we usually perform CNC machining on thin wall ceramic parts, are there any of the following problems in the process?

There are problems in the processing of thin wall ceramic parts

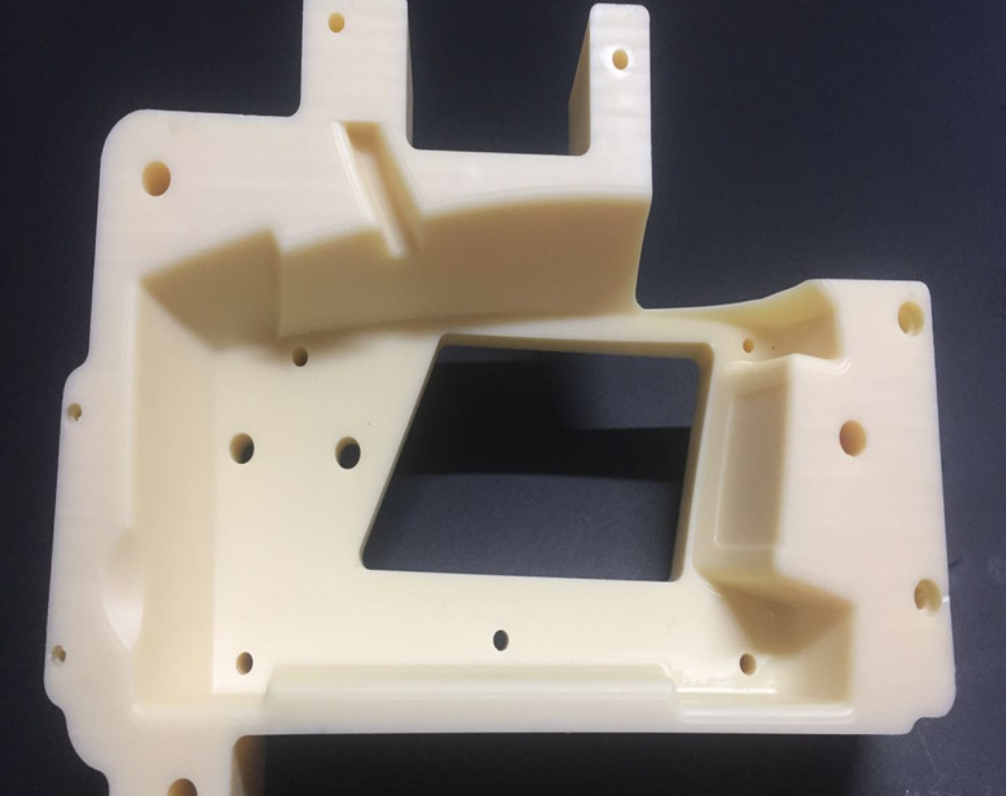

The CNC machining process of thin wall ceramic parts requires that the thickness of the entire ceramic part does not exceed 1mm. Although the overall structure of thin wall ceramic parts is relatively compact, their rigidity is poor and their strength cannot meet the actual production and processing requirements. In the actual processing process, due to the inherent reasons of the material itself, the processing effect often does not meet the actual design requirements. Therefore, reprocessing should be carried out by improving the process to ensure the processing effect.

During the process of clamping ceramic parts, on the basis of ensuring the compactness of the entire clamping, appropriate adjustments and optimizations should be effectively carried out, and the management and rotation matrix should be controlled and optimized as comprehensively as possible. Meanwhile, since the clamp itself is affected by the main shaft, only by ensuring that all the center of gravity controls are concentrated at the top of the main shaft can the comprehensive development of all tasks be effectively guaranteed. Effective suspension depth control and selection should be carried out on the actual state of the current ceramic parts to ensure that the entire length meets the current design requirements. Meanwhile, during the production process, it is also necessary to ensure that the strength and hardness of the clamps meet the current actual needs, so as to reduce the damage of the clamps and ensure the long-term operation of all clamps as much as possible. However, in actual operation, the control of cutting tools mainly focuses on the numerical control machining and cutting process of thin wall ceramic parts. Many operators do not select the entire cutting Angle, ultimately resulting in the entire cutting Angle not meeting the current actual requirements, to ensure that the established processing demands only require a small effort, and ultimately ensure that the ceramic parts can be effectively controlled on the basis of variation.

The following two process optimization measures for CNC machining methods of thin wall ceramic parts:

Optimize the processing technology

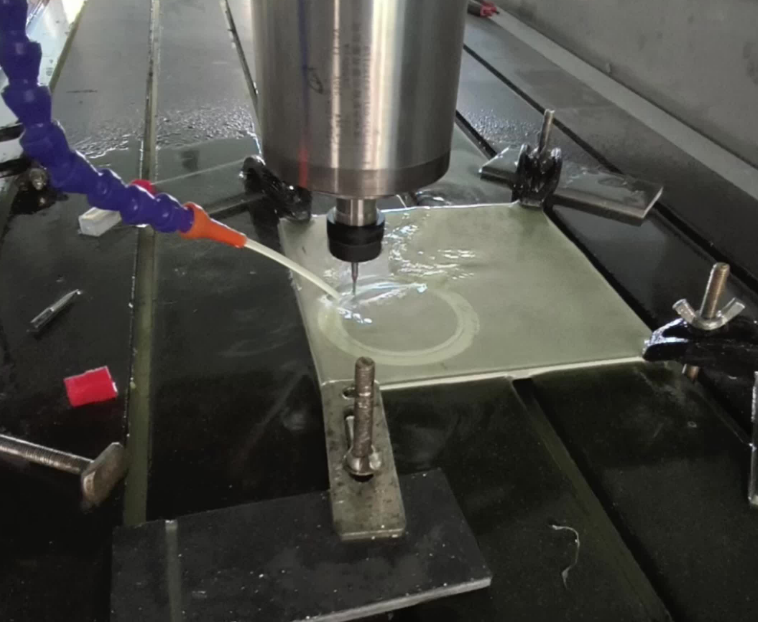

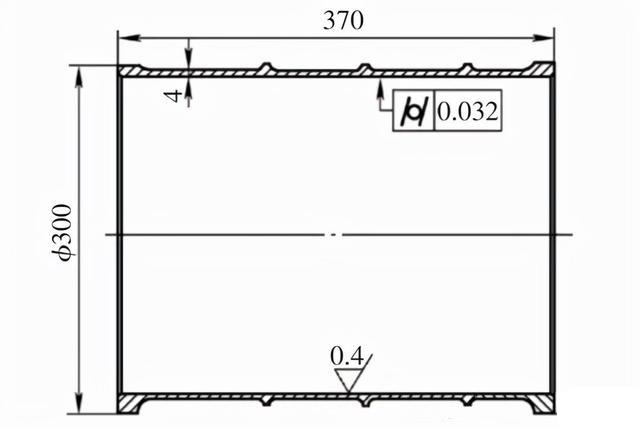

Compared with traditional processing techniques, through this numerical control processing method for thin wall ceramic parts, the adopted technological design and processing can significantly reduce data errors during the processing, thereby effectively ensuring the actual quality of current ceramic parts products. Through a comprehensive analysis of the relevant technical processes of numerical control machining of thin wall ceramic parts, at present, the methods of numerical control machining of thin wall ceramic parts mainly shift from rough machining to fine machining gradually. In the process of rough machining using numerical control technology, it is often necessary to analyze the actual situation of the current ceramic parts and then formulate the target process processing method. This can not only improve the processing quality but also reduce the occurrence of losses. After the rough machining is completed, the technical equipment can be used for semi-finishing, mainly to extract the relevant materials on the surface of the ceramic parts, effectively ensuring the accuracy of the later processing data. During the fine processing, to effectively implement fine processing, accurate data analysis must be conducted and processing management should be carried out through meticulous technical means. For instance, the outer circle can be finely milled for processing and optimization, ultimately ensuring that the overall ceramic parts meet the current design requirements. The CNC machining of thin wall ceramic parts itself has relatively high processing requirements. In order to effectively improve the fine manufacturing of materials and minimize resource consumption, in the CNC machining process of thin wall ceramic parts, it is necessary to first do a good job in CNC deformation control, and try to make it the current processing method and processing parameters as much as possible, effectively propose a scientific processing plan, and ultimately ensure that the deformation value is within the controllable range, as shown below.

Change the processing method

The processing methods of CNC machining for thin wall ceramic parts mainly include three aspects: process design, tool clamping control for ceramic parts, etc. In the actual numerical control machining process of thin wall ceramic parts, the analysis process of numerical control policies should be effectively completed, the actual load capacity of the hardware in the current actual machining process should be clarified, the relationship between the load sequence and deformation should be effectively analyzed, and finally a targeted process design method should be proposed. F=KU. This is the formula of the current main calculation process. F serves as the load array for the CNC machining of thin wall ceramic parts, and KU represents the light matrix, which is used as the technical value for machining deformation. Through the comprehensive analysis among the three, it can be observed that when the value of the load array gradually decreases, the light matrix should be effectively adjusted, ultimately effectively ensuring the overall improvement of the quality of ceramic parts. And enhance the appropriate material strength. The value of KU should be comprehensively adjusted and optimized, and finally the appropriate processing and production method should be selected.

Next, let's talk about the estimation of the optimization effect of the CNC machining process for thin wall ceramic parts

Effectively control the deformation of ceramic parts

In light of the current actual situation, during the implementation of CNC machining for thin wall ceramic parts, the processing design should be carried out in accordance with the actual design requirements, as shown in Figure 1. First, rough machining should be carried out, followed by semi-finishing, and finally finishing should be completed. On the basis of implementing processing, surface control should be carried out first, and it should be optimized as much as possible on the original basis. However, during the construction process of blank ceramic parts, it is believed that the internal environment is affected by the external environment, and with the addition of heating treatment, it is very easy for the current ceramic parts to deform, ultimately affecting the actual size and design quality of the CNC machining of thin wall ceramic parts. Due to the continuous change in the degree of wall thickness, its rigid structure cannot meet the actual production needs, so its own guidance will undergo certain changes. In the continuous reduction of wall thickness, cutting vibration occurs, ultimately resulting in the actual product dimensions failing to meet the actual design requirements, and the core surface cannot be guaranteed either. The numerical control processing technology mainly relies on actual design parameters and clear scientific processing methods. However, due to external influences and various limitations, it often directly leads to a gradual increase in processing difficulty, and the product quality cannot meet the actual production design requirements. Eventually, the precision achieved has a large gap from the expected production precision and cannot withstand the predetermined clamping force, resulting in deformation phenomena. This leads to the low quality of CNC machining of thin wall ceramic parts.

Comprehensively optimize the process effect

To comprehensively improve the process quality, it is necessary to carry out technical optimization from two aspects: the process improvement plan and the processing method improvement, so as to comprehensively enhance the process quality.

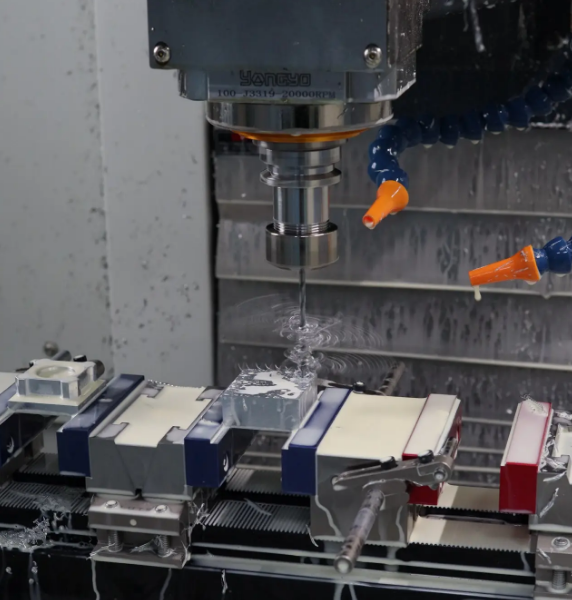

(1) Process improvement plan In light of the current actual design requirements, during the process of CNC machining of thin wall ceramic parts, the entire end face should be roughly milled first, and then the initial processing should be completed through heating treatment. The following measures were taken: The radial clamping force was changed to axial compression, so that the ceramic parts were only affected by the axial force and not by the radial force, which greatly reduced the clamping deformation of the ceramic parts. After the initial processing is completed, the processing should be carried out by reducing the heat, and finally the fine processing should be completed. During the fine processing, the allowance should be arranged and managed in advance to effectively avoid many construction methods that cannot be implemented in accordance with the established processing requirements due to allowance factors, and to reduce related problems such as the inner circle design form that cannot be corrected due to insufficient allowance.

(2) Improve the processing methods. To ensure that the actual state of the hole is within the designer's control range, during the fine machining process, the light tool operation technology should also be utilized as much as possible to improve the quality of CNC machining and ensure the machining effect. To improve the processing methods, it is required that the operators select targeted machine processing based on the actual processing of ceramic parts to ensure the processing intensity, achieve the stability of processing ceramic parts as much as possible, and at the same time ensure that the materials used at the current stage meet the established working requirements, reducing the damage to ceramic parts caused by the damage of processing equipment.

By analyzing the actual situation of CNC machining of thin wall ceramic parts and combining the actual effect of process transformation, only by optimizing the CNC machining of thin wall ceramic parts can the processing quality be effectively improved, problems such as vibration lines and deformation be reduced, and the actual roughness of the product size and surface be effectively guaranteed to meet the current design management requirements. Through effective analysis and research on the results of relevant cases, we not only need to combine practical production experience for analysis and optimization, but also raise different problems caused by different processing methods, so as to ensure that the processing quality is not limited by production experience as much as possible, and ultimately cause damage to the CNC processing quality of thin wall ceramic parts. Therefore, only by constantly enhancing the quality of numerical control processing simulation analysis and improving processing methods through effective means can the processing quality be improved as much as possible and all controllable processing qualities be ensured.